Bibumen fabric

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

Coverage

Corrosion Protection Chemical Plant Storage Tank Anticorrosior Advantage

Good Waterproof Good Temperature Resistance Not Easy To Wear

Easy To Construct Good Thermal Insulation Not EasyTo Tear Product Display

Product Overview

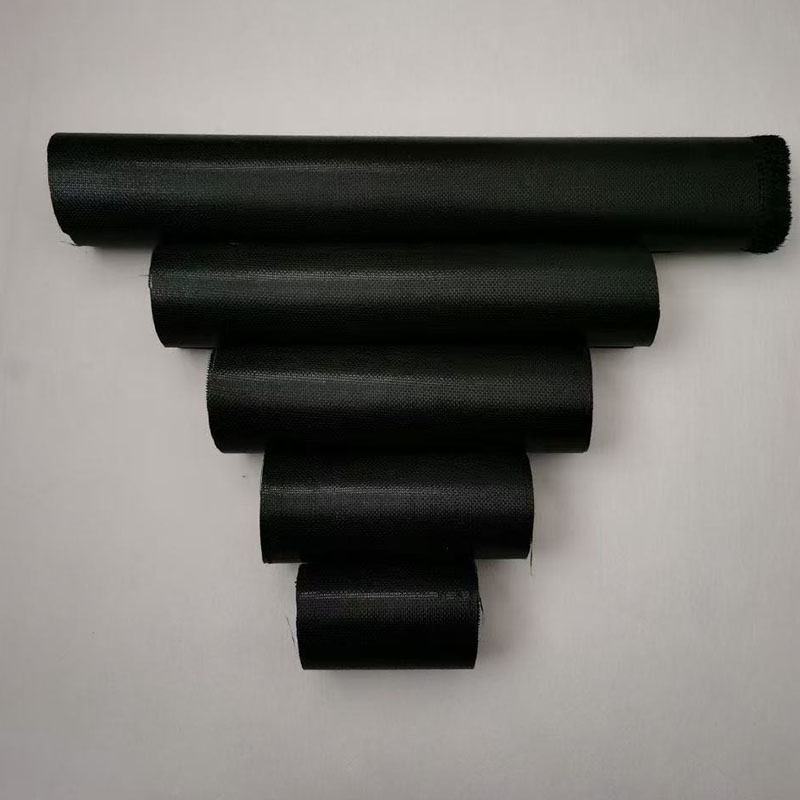

Bitumen fabric is made using polyester fiber as the base fabric, which is then coated with asphalt as the primary raw material.

Application Scope

Bitumen fabric is widely used in waterproofing projects across construction, transportation, and water conservancy fields, such as:

Roof waterproofing

Basement waterproofing

Tunnel waterproofing, etc.

Product Features

Excellent Waterproof Performance:

The main function of bitumen fabric is waterproofing. The asphalt coating on the surface effectively blocks water penetration.Strong Aging Resistance:

Specially treated bitumen fabric can resist aging caused by environmental factors like UV rays and oxidation, extending its service life.Wide Temperature Tolerance:

bitumen fabric maintains stable performance across a broad temperature range. It can be unrolled and installed at low temperatures, and remains stable without slippage or bubbling at high temperatures.Good Corrosion Resistance:

bitumen fabric is resistant to a variety of chemicals, making it suitable for complex environments.Storage & Transportation

I. Storage Technical Requirements

Classified Storage:

Different types and specifications of bitumen fabric must be stored separately—no mixed stacking is allowed.Environmental Conditions:

Avoid exposure to sunlight and rain; storage areas must be well-ventilated and dry.

Storage temperature should not exceed 50°C (especially for modified asphalt rolls).

Stacking Method:

Must be stored vertically; stacking height must not exceed two layers. Use wooden boards between layers to prevent sticking.

For long-term storage, the surface may be sprinkled with talcum powder or fine sand to prevent adhesion.

Safety Protection:

Storage sites should be equipped with fire-fighting equipment (fire extinguishers, fire sand) and anti-static devices.

Coal tar asphalt, which is toxic, must be sealed during storage, and operators should wear protective gear.

Shelf Life:

The storage period for modified asphalt rolls must not exceed 1 year from the production date.II. Transportation Technical Requirements

Vehicles:

Ordinary trucks can be used for transport, but the truck bed must be clean and dry, and equipped with a waterproof tarp.

Loading Norms:

Rolls must be stored upright and secured. The stacking height must not exceed two layers, and tilting or heavy pressure must be avoided.

Application Process

The waterproofing treatment using bitumen fabric (waterproof rolls) primarily includes the following steps: base treatment, roll application, seam treatment, and protective layer construction. Common application methods include torch-on (hot-melt), cold adhesive, self-adhesive, and spray-on methods.

Specific Process Flow:

I. Base Treatment

Clean the Base Surface:

Remove debris, dust, and oil stains. Ensure the base is dry, flat, and repair any cracks or holes.

II. Apply Primer

Enhance Adhesion:

Evenly brush on a special primer (e.g., cold-applied primer). Wait for it to dry before proceeding with subsequent work.

III. Roll Application (Torch-On Method Example)

Snap Baseline:

Mark alignment lines based on roof slope to ensure straight installation.

Heat the Roll:

Use a torch to heat the underside of the roll until the asphalt melts (torch-on method), or apply adhesive (for cold adhesive method).

Press Down the Roll:

Start from the lower end and press the roll while heating, squeezing out air to ensure close adhesion to the base.

IV. Seam Treatment

Handle Overlaps:

Overlapping areas (≥70mm for long edges, ≥100mm for short edges) must be heated or glued and pressed firmly to ensure a tight seal.

V. Protective Layer Construction

Protective Measures:

Lay a protective layer (e.g., mortar) or apply a protective waterproof coating to prevent damage during subsequent construction.

Additional Method Notes:

Cold Adhesive Method:

Rolls are installed by applying adhesive directly without heating, suitable for flammable environments.Self-Adhesive Method:

The protective film is peeled off and the roll is directly adhered, offering easy operation.Spray-On Method:

Liquid asphalt is sprayed to form a waterproof film, suitable for complex surfaces.

ABOUT US

CT Waterproof Coatings is a dynamic exporter focusing on supplying waterproof coatings worldwide. We provide solutions to various projects including residential construction, commercial & industrial buildings, infrastructure projects, marine & coastal projects, agricultural projects, roads & highways and storage & warehousing. Established in 2010, we have built a reputation for delivering exceptional value, reliability and unparalleled customer service.

SHIPPING SCENE

FAQ

Are you trading company or manufacturer?

We are manufacturer.So we have a lower price than trading company.

What is the payment way?

TT, L/C at sight, West Union,Online Bank Payment.

What are your terms of delivery?

We can accept EXW, FOB, ClF, etc. You can choose one which is the most convenient for you.

Do you accept OEM or ODM order?

Yes, we accept both OEM and ODM for customers.

How does your factory do regarding quality control?

Quality is priority,. We always attach great importance to quality control from the very beginning to the end. We have a professional QA/QC team to ensure the quality.

How about the delivery time ?

7-15 days after receive the deposit or LC at sight

Do you provide sample ?ls it free or extra ?

Yes,we can provide free sample for quality inspection.According to our company police , you should assume the freight ,and we will return the freight if you place the order.

Why choose us ?

We are professional manufacturer, and we can provide the best product ,competitive priceand excellent service.

Bibumen fabric

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.