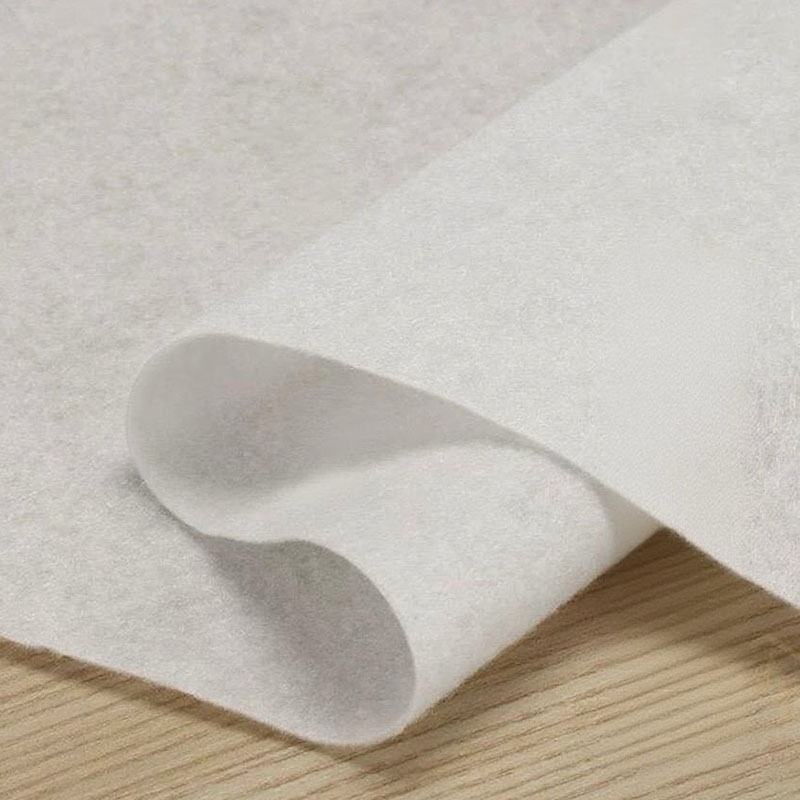

Terylene fabric

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

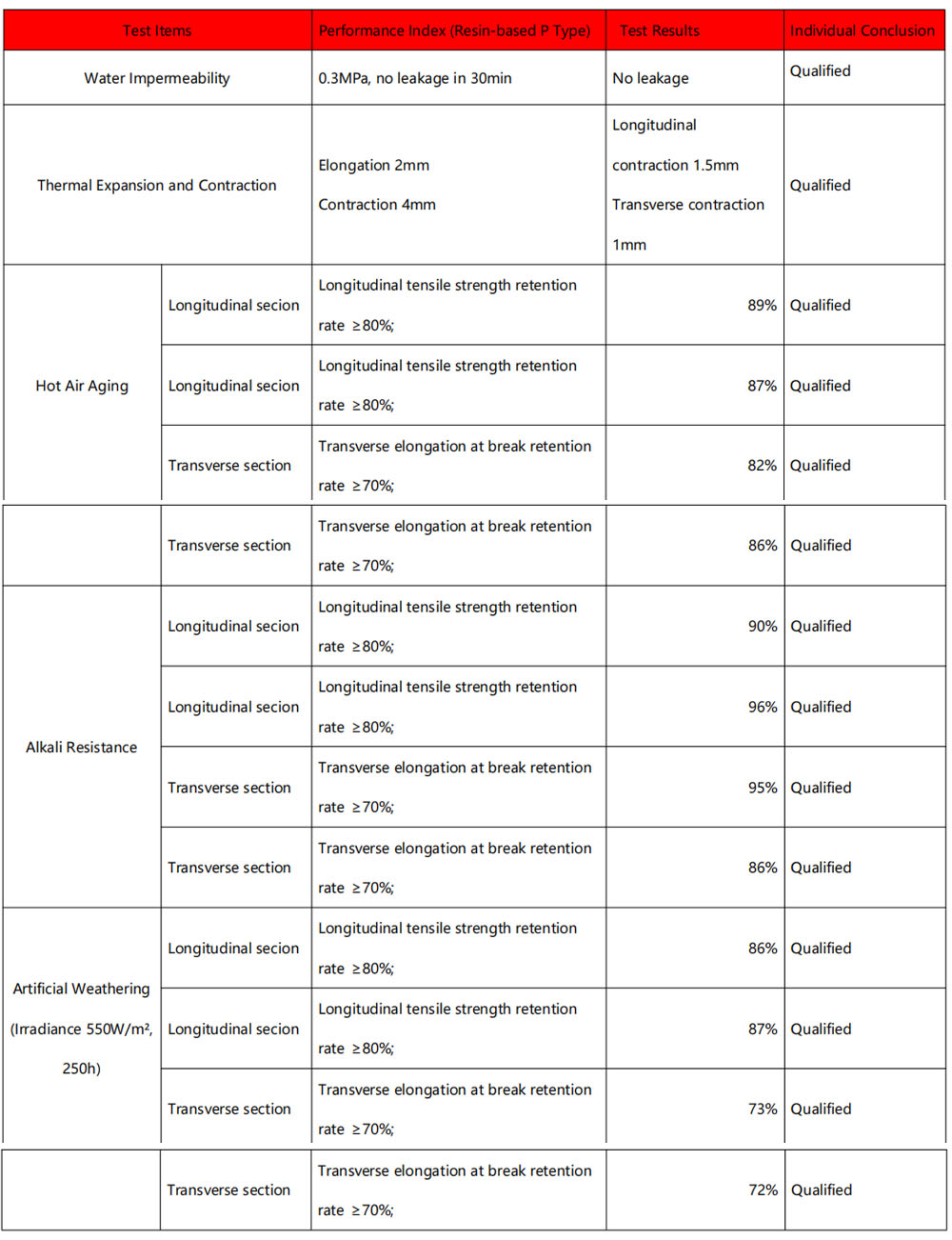

PERFORMANCE INDICATORS

Easy construction

1. Clean the ground.pour the mixedcement slurry onthe base surface.and scrape it flatwith a scraper. 2. When laying thepolypropylene cloth,water and air must bdriven out to ensurethere is no hollowing 3.Apply a protectivelayerof cement slurryon the polypropylenecloth, preferably morethan 2cm Application

Bathroom Waterproofing Basement Moisture Proofing Basement proofing

Tile-roofed House Leak Proofng Gutter Waterproof Swimming pool Product Display

Product Overview

Terylene Fabric Waterproof Membrane is a type of polymer waterproofing material primarily made from polyethylene and new polyester non-woven filament. Through a unique raw material formulation and manufacturing process, it exhibits several excellent properties, including outstanding waterproof performance, good weather resistance, corrosion resistance, and high tensile strength. The main components of the terylene fabric waterproof membrane include polyethylene, high-strength polyester non-woven fabric, UV light blockers, anti-aging agents, and other polymer materials. These materials are processed through an automated production line in a one-time extrusion molding process to create a multi-layered polymer waterproof membrane.

Application Scope

Terylene fabric waterproof membranes are widely used in waterproofing projects for buildings, roads, bridges, and water conservancy works. Specific applications include:

Roof Waterproofing:

Used for roof waterproofing of all types of industrial and civil buildings.Ground Waterproofing:

Suitable for ground damp-proofing, vapor barriers, and indoor floor moisture treatment.Underground Waterproofing:

Used in basements, cold storage facilities, pools, and other underground spaces.Special Environments:

For pollution protection in complex environments such as metallurgy and chemical industries.Product Features

Waterproof Performance:

The polyester fabric waterproof membrane has excellent waterproof performance and can effectively resist various harsh environments, including high temperatures, low temperatures, and humidity.Durability and Aging Resistance:

With the addition of anti-aging agents and stabilizers, the membrane can maintain its waterproof performance over a long period, promising a service life of over 50 years.Environmental Friendliness:

This material is non-toxic and environmentally friendly, meeting green building requirements.Ease of Construction:

Its surface is rough and uniform, making it easy to bond with various base materials and suitable for direct bonding during the curing process of cement materials.Strong Adaptability:

Suitable for various construction and engineering applications, including roofs, floors, moisture-proofing, vapor barriers, and interior floor moisture control.Storage & Transportation

Storage Method

Environmental Requirements:

Store in a dry, ventilated, and cool warehouse, avoiding direct sunlight and rain. Storage temperature should be between 5℃ and 35℃ with relative humidity not exceeding 60%.Storage Method:

Rolls should be laid flat or stacked without excessive bending or folding. Keep rolls off the ground to prevent dampness and contamination. Different specifications and types should be stored separately with clear labeling.Packaging Requirements:

Packaging must be secure and well-sealed to prevent moisture, dust, and other contaminants. The package should clearly indicate product name, specifications, quantity, manufacturer, and production date.Storage Period:

The storage period should not exceed 12 months from the production date. Rolls stored beyond this period must be inspected and treated before use and should not be used in waterproof projects unless approved.Transportation Method

Transportation Mode:

Can be transported by vehicle, train, or ship using the most economical and reasonable method.Loading and Unloading Requirements:

Avoid impact, squeezing, and damage during loading and unloading. Different specifications and types should be handled separately and stacked neatly using appropriate tools and equipment such as forklifts and cranes to ensure safety.Transportation Packaging:

Packaging must be effective in preventing moisture, dust, and other contaminants during transport. It should be secure and well-sealed to protect the product from damage.Transportation Time:

Should be reasonably arranged according to the construction schedule and material supply plan. Long transit times should be avoided to prevent expiration or damage. Maintain communication with suppliers and construction teams to ensure timely delivery to the construction site.Precautions

Avoid Contact with Harmful Substances:

Avoid contact with acids, alkalis, mineral oils, petroleum jelly, and other chemicals that can affect performance. Also avoid contact with temperatures above 80°C to prevent deformation.Intact Packaging:

During storage and transportation, ensure packaging remains undamaged. Store in ventilated and dry places. Stacks should not exceed the height of five horizontally placed rolls.Application Process

Base Surface Treatment:

Surfaces such as walls or roofs must be flat, dry, solid, and free of oil, dust, and debris, or they will affect adhesion and waterproof performance.Primer Coating (Base Coat):

Apply primer adhesive to form a uniform moisture barrier and enhance adhesion to the base surface. Suitable for vertical surfaces. Ensure even coating without gaps, avoiding penetration by tools like brushes, rollers, or putty knives.Intermediate Coat:

Apply intermediate adhesive on top of the primer layer. This adhesive has higher viscosity, doesn’t flow easily, and allows control over coating thickness. It acts as a crucial bonding layer. The application must be even and complete without burrs, blisters, or raised areas, and must meet design thickness requirements to avoid separation in the waterproof layer.Top Coat:

Apply the topcoat adhesive over the intermediate layer. It has excellent bonding properties and flexibility to prevent moisture intrusion between layers. Ensure even application and proper thickness. Typically used for indoor floor surfaces for optimal results.Construction Workflow

Base Layer Treatment:

Clean, treat, and repair the base layer.Preparation:

Confirm the construction plan and inspect waterproofing materials.Primer Application:

Apply the base coat to restore the flatness and strength of the layer.Intermediate Layer Application:

Apply by rolling or spraying. In cold or damp weather, extend curing time as needed.Topcoat Application:

Apply the top coat to restore flatness and strength.Construction Notes

Avoid Construction on Rainy Days:

Only construct when temperatures are above 5℃ and relative humidity is below 85%.Joint Treatment:

Indirect seams should adhere to each other, while direct seams should be pressed together to prevent water leakage.Full Adhesion:

The membrane should be fully bonded to the substrate with no gaps.Correct Application Order:

Do not reverse the base, intermediate, and topcoat order, as it will affect waterproof performance.Reference Only:

This construction guide is for reference; actual processes should be adjusted based on specific conditions.Conclusion

The construction process of polyester fabric waterproof membrane involves steps such as base surface treatment, primer, intermediate, and topcoat application. Attention must be paid to weather conditions and joint treatments to ensure optimal waterproof performance. For more detailed construction information, personnel should follow the standardized procedures and precautions accordingly.

ABOUT US

CT Waterproof Coatings is a dynamic exporter focusing on supplying waterproof coatings worldwide. We provide solutions to various projects including residential construction, commercial & industrial buildings, infrastructure projects, marine & coastal projects, agricultural projects, roads & highways and storage & warehousing. Established in 2010, we have built a reputation for delivering exceptional value, reliability and unparalleled customer service.

SHIPPING SCENE

FAQ

Are you trading company or manufacturer?

We are manufacturer.So we have a lower price than trading company.

What is the payment way?

TT, L/C at sight, West Union,Online Bank Payment.

What are your terms of delivery?

We can accept EXW, FOB, ClF, etc. You can choose one which is the most convenient for you.

Do you accept OEM or ODM order?

Yes, we accept both OEM and ODM for customers.

How does your factory do regarding quality control?

Quality is priority,. We always attach great importance to quality control from the very beginning to the end. We have a professional QA/QC team to ensure the quality.

How about the delivery time ?

7-15 days after receive the deposit or LC at sight

Do you provide sample ?ls it free or extra ?

Yes,we can provide free sample for quality inspection.According to our company police , you should assume the freight ,and we will return the freight if you place the order.

Why choose us ?

We are professional manufacturer, and we can provide the best product ,competitive priceand excellent service.

Terylene fabric

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.