Contact Us

Phone: +86-13389906750

WhatsApp: +8613389906750

Add:Room 1007, Xianzhigu Tower, Hua Yuan Industrial Area, Tianjin

This product is a kind of high elastic colorful polymer waterproof coating, which is based on acrylic elastic emulsion for waterproof, produced with a certain amount of modifiers, active agents, additives and fillers through scientific processing.

A grouting machine is a mechanical device used for foundation treatment and structural reinforcement. It works by injecting specific grouting materials into the foundation or internal structures to strengthen the soil, prevent foundation settlement, and enhance overall stability. A typical grouting machine is composed of components such as a grout pump, mixer, and piping system. It can inject various types of grouting materials (such as cement slurry, epoxy resin, etc.) into voids that need to be filled or reinforced, thereby improving the load-bearing capacity and durability of structures.

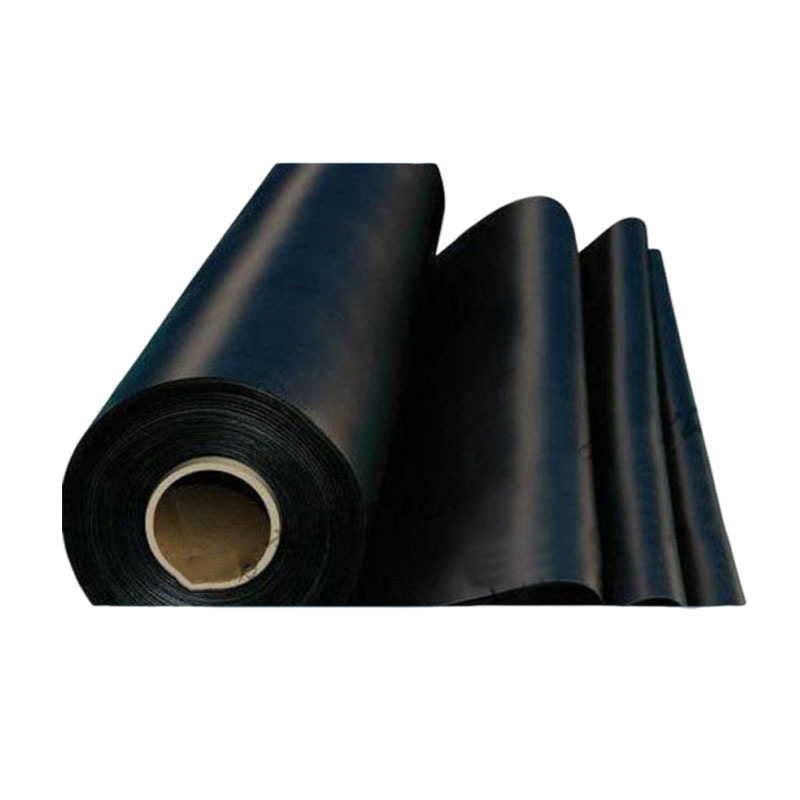

Terylene Fabric Waterproof Membrane is a type of polymer waterproofing material primarily made from polyethylene and new polyester non-woven filament.

Waterborne polyurethane waterproof coating

Water-based polyurethane waterproof coating is a sealing material made of high polymer elastic materials. It has excellent adhesion and waterproof properties, with strong bonding capabilities to mortar, cement-based surfaces, stone, and metal products.

The Transparent Waterproof Glue is a versatile, high-performance adhesive designed for effective water resistance and strong bonding in construction applications.

Tar paper is a general term for asphalt-based waterproofing membranes. It usually refers to waterproof roll materials made with a base layer (such as raw paper, fabric, fiber felt, or metal foil) that is impregnated or coated with asphalt, modified asphalt, or modified tar, and then topped with surface materials.

Polymer waterproof breathable membrane

Polymer Waterproof Breathable Membrane (Breathable Paper) is a new type of polymer waterproofing material. In terms of manufacturing process, the technical requirements for waterproof breathable membranes are significantly higher than those of conventional waterproof materials. In addition, these membranes also possess functional characteristics not found in other waterproofing materials.

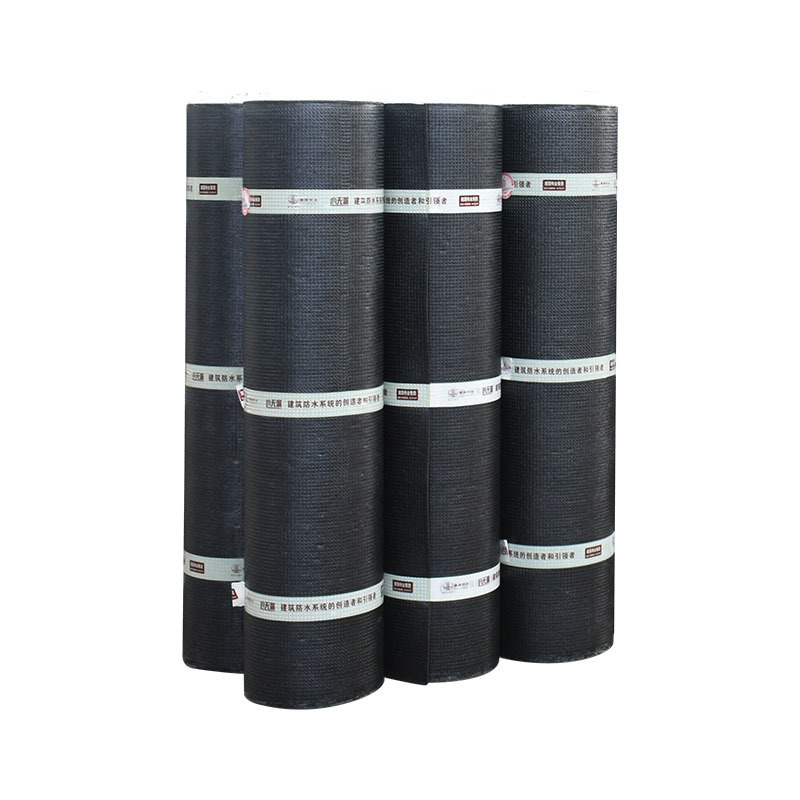

SBS (Styrene-Butadiene-Styrene) modified bitumen waterproofing membrane is a high-performance waterproof material. It is made by using SBS rubber-modified asphalt as the coating layer, with fiberglass mat, polyester mat, or fiberglass-reinforced polyester mat as the reinforcement layer. Both sides are covered with isolating materials. This product has excellent properties such as heat resistance, cold resistance, corrosion resistance, aging resistance, good thermoplasticity, high tensile strength, high elongation, and strong tear resistance.

Product OverviewPolyester cloth is a synthetic fiber material made from polyester fibers, which are petrochemical products formed by the polymerization of polyester monomers into linear macromolecular compounds. Polyester cloth is known for its tear resistance, abrasion resistance, waterproof and moisture-resistant properties, as well as its high softness and ease of processing.Application ScopeHome Furnishings: Widely used in sofas, curtains, bedding, and other household items.Apparel Industry: Used to make clothes, hats, shoes, etc., due to its softness and ease of processing.Industrial Use: Employed in the manufacture of industrial products such as filters and conveyor belts.Construction Industry: Due to its breathability and durability, it is used for thermal insulation, waterproofing, and insulation in buildings.Other Fields: Also used in making luggage, tents, car canopies, and more.Product FeaturesAbrasion Resistance: Excellent resistance to wear and friction, suitable for long-term use.Tear Resistance: High strength and toughness, offering strong resistance to tearing.Waterproof and Moisture-Proof: Treated surface provides effective water and moisture resistance, suitable for waterproof material applications.Corrosion Resistance: Resists most chemical corrosion, making it less susceptible to chemical damage.Bright Colors: Good dyeing properties allow for vivid and vibrant colored fabrics.Storage & Transportation of Waterproof Polyester ClothStorage GuidelinesEnvironmental Requirements: Store in a dry, ventilated, and cool warehouse. Avoid direct sunlight and rain. Keep temperature between 5°C and 35°C, and relative humidity below 60%.Storage Method: Store flat or in stacks, avoiding excessive bending or folding. Rolls should be kept off the ground to prevent moisture and contamination. Different specifications and types should be stored separately and clearly labeled.Moisture and Mildew Prevention: Use moisture-proof setups like pads or desiccants. Regularly rotate and air out materials to prevent mold growth.Avoid Direct Sunlight: UV rays can damage waterproof materials and degrade performance. Store in shaded areas or use shading equipment.Fire Safety: As many waterproof materials are flammable, smoking and open flames should be strictly prohibited. Fire safety equipment should be available.Transportation GuidelinesMode of Transport: Choose based on the situation—by truck, train, or ship—opting for economical and efficient transport methods.Loading and Unloading: Avoid impacts, crushing, and damage. Handle different specifications separately. Use appropriate tools like forklifts or cranes for safe handling.Packaging Requirements: Ensure secure, sealed packaging to prevent moisture, dust, and other contaminants. Packaging should be durable and include clear labeling: product name, specifications, quantity, manufacturer, and production date.Application Process of Waterproof Polyester ClothI. Thorough Preparation Before ConstructionBefore starting waterproofing with polyester cloth, comprehensive preparation is essential:Survey the site to ensure safety and stability.Ensure the quality of polyester cloth and auxiliary materials meets required standards.Formulate a detailed construction plan outlining steps and objectives.1. Substrate PreparationCheck the substrate for smoothness, dryness, oil-free surfaces, sandiness, and cracks. Uneven or cracked areas should be repaired—e.g., leveling with cement mortar or using special repair materials. Clean the surface thoroughly to ensure it’s dust- and debris-free.2. Material PreparationInspect all materials—polyester cloth, waterproof coatings (e.g., polyurethane, acrylic), and auxiliary materials (primers, adhesives). Check specifications, production dates, and quality certificates to ensure compliance. Calculate material quantity based on the construction area to avoid waste.3. Construction EnvironmentMaintain an ambient temperature above 5°C and relative humidity below 85% during construction. Avoid adverse weather like rain, snow, or strong winds. Ensure good ventilation to reduce harmful gas exposure.II. Construction ProcessPrimer ApplicationAfter substrate preparation, apply a primer to improve adhesion and seal micro-pores on the surface. Apply evenly and let dry completely before continuing.Laying the Polyester ClothCut the cloth to the required size and lay it on the primed surface. Ensure overlap is at least 10 cm to maintain continuity. Use adhesive or waterproof coating to bond the fabric tightly to the base without gaps or wrinkles.Applying Waterproof CoatingAfter laying the cloth, apply a waterproof coating evenly over the surface, ensuring it penetrates the fibers for a dense waterproof layer. Pay extra attention to critical areas like corners and pipe bases, applying additional coats as needed.Multi-Layer Construction (If Required)For high waterproofing standards, alternate layers of cloth and waterproof coating to increase thickness and durab

Non-Woven Geotextile in Civil Engineering is also known as short-fiber geotextile or non-woven fabric, is primarily made from polyester staple fibers and produced using non-woven processes. It has multiple functions such as separation, filtration, drainage, reinforcement, protection, and maintenance, and is widely applied in highways, railways, civil engineering, hydraulic engineering, and environmental protection projects.

Bitumen fabric is made using polyester fiber as the base fabric, which is then coated with asphalt as the primary raw material.

Butyl waterproof membranes are a type of polyethylene-polypropylene composite waterproofing membrane made from linear low-density polyethylene resin, aging inhibitors, stabilizers, tackifiers, and high-strength new spunbond polypropylene nonwoven fabric.