Non-woven fabric

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

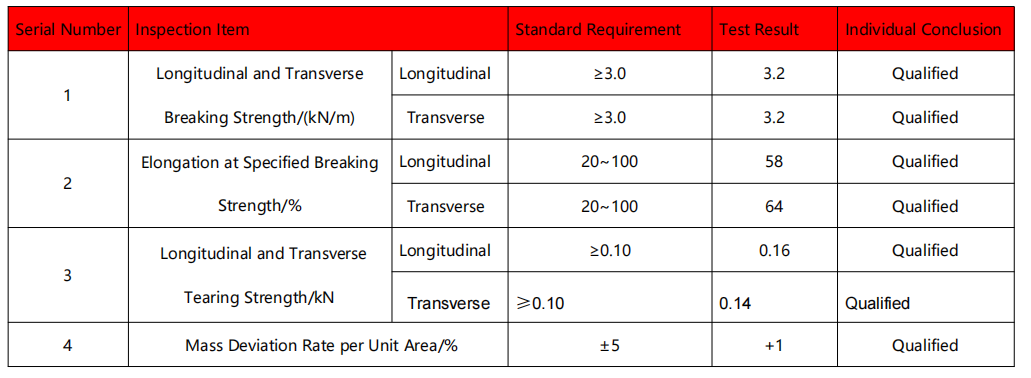

PERFORMANCE INDICATORS

EApplication

Bathroom Waterproofing Basement Moisture Proofing Basement proofing

Tile-roofed House Leak Proofng Gutter Waterproof Swimming pool Product Display

Non-Woven Geotextile in Civil Engineering is also known as short-fiber geotextile or non-woven fabric, is primarily made from polyester staple fibers and produced using non-woven processes. It has multiple functions such as separation, filtration, drainage, reinforcement, protection, and maintenance, and is widely applied in highways, railways, civil engineering, hydraulic engineering, and environmental protection projects.

Application Scope

In infrastructure projects such as highways (including temporary roads), railways, embankments, earth-rock dams, airports, and sports fields, it is used to reinforce weak foundations while providing separation and filtration. When placed on riverbanks, lake shores, or sea coasts, geotextiles help prevent soil erosion caused by water flow.

As reinforcement in retaining wall backfill, or for anchoring facing panels of retaining walls. Also used in wrapped retaining walls or bridge abutments.

Reinforcing flexible pavements, repairing pavement cracks, and preventing reflective cracking on road surfaces.

Stabilizing gravel slopes and reinforced soil, preventing soil erosion and frost heave damage in cold conditions.

As a separation layer between ballast and subgrade, or between the subgrade and soft foundation.

For separation in man-made fills, rubble, or material stockpiles and foundation soils, and between different frost soil layers, also playing filtration and reinforcement roles.

As a filtration layer on upstream slopes of initial construction phases of ash dams or tailings dams, or in the drainage systems of retaining wall backfills.

As a filtration layer around subsurface drainage pipes or gravel drainage trenches.

In hydraulic engineering, used in wells, pressure relief wells, or oblique pressure pipes as a filtration layer.

As a separation layer between geotextiles and the foundation in roads, airports, railways, and man-made rubble layers.

For vertical or horizontal drainage within earth dams, helping to dissipate pore water pressure.

Behind impermeable membranes in dams or under concrete protective layers, used for drainage purposes.

To drain seepage around tunnels, reducing hydrostatic pressure on tunnel linings and seepage around structures.

For drainage in man-made fill foundations or sports field foundations.

Product Features

Filtration (Reverse Filtration): Allows fluids to pass through while retaining soil or other particles influenced by hydraulic forces.

Separation: Prevents intermixing of different materials, maintaining the integrity and functionality of the structure and improving load-bearing capacity.

Drainage: Acts as an excellent water conduit within soil structures, enabling the removal of excess liquids and gases.

Reinforcement: When embedded in soft or unstable soils, it increases the soil's strength and overall stability.

Protection: Effectively distributes, transfers, or dissipates concentrated stress to prevent damage to the soil structure under external forces.

Chemical and Physical Stability: Offers good durability and stability, simplifying design, facilitating construction, extending service life, and reducing construction costs to varying degrees.

Storage & Transportation

Geotextile rolls must be protected from damage before installation and deployment.

Rolls should be stacked on a flat, well-drained surface, with a stacking height not exceeding four rolls. Each roll must be easily identifiable with its label visible.

Rolls must be covered with opaque material to protect against UV degradation.

During storage, labels and documentation must remain intact.

During transport (including moving from storage to the work site), rolls must be protected from physical damage.

Damaged rolls must be repaired, and severely worn or chemically contaminated rolls must not be used in the project.

Application Process

Manual unrolling is commonly used. The fabric should be flat and allow for appropriate deformation margins.

Installation of long or short fiber geotextiles is typically done by lapping, sewing, or welding:

Sewing or welding width: generally ≥ 10 mm

Overlap width: generally ≥ 20 mm

Geotextiles expected to be exposed long-term must be sewn or welded.

Sewing Requirements:

All seams must be continuous (spot stitching is not allowed).

Before overlapping, the overlap should be at least 150 mm.

The minimum stitch distance from the edge of the fabric should be at least 25 mm.

Seams should include at least one row of lock-stitch seam.

Sewing thread should have a minimum tensile strength of 60N, made from resin-based material with chemical and UV resistance equal to or greater than the geotextile itself.

Any "missed stitches" must be re-stitched at the affected area.

Note: Measures should be taken to prevent soil, particles, or foreign matter from entering the geotextile layer during and after installation. Depending on the terrain and intended function, joints may be made via natural overlapping, stitching, or welding.

ABOUT US

CT Waterproof Coatings is a dynamic exporter focusing on supplying waterproof coatings worldwide. We provide solutions to various projects including residential construction, commercial & industrial buildings, infrastructure projects, marine & coastal projects, agricultural projects, roads & highways and storage & warehousing. Established in 2010, we have built a reputation for delivering exceptional value, reliability and unparalleled customer service.

SHIPPING SCENE

FAQ

Are you trading company or manufacturer?

We are manufacturer.So we have a lower price than trading company.

What is the payment way?

TT, L/C at sight, West Union,Online Bank Payment.

What are your terms of delivery?

We can accept EXW, FOB, ClF, etc. You can choose one which is the most convenient for you.

Do you accept OEM or ODM order?

Yes, we accept both OEM and ODM for customers.

How does your factory do regarding quality control?

Quality is priority,. We always attach great importance to quality control from the very beginning to the end. We have a professional QA/QC team to ensure the quality.

How about the delivery time ?

7-15 days after receive the deposit or LC at sight

Do you provide sample ?ls it free or extra ?

Yes,we can provide free sample for quality inspection.According to our company police , you should assume the freight ,and we will return the freight if you place the order.

Why choose us ?

We are professional manufacturer, and we can provide the best product ,competitive priceand excellent service.

Non-woven fabric

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.