Polyester cloth

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

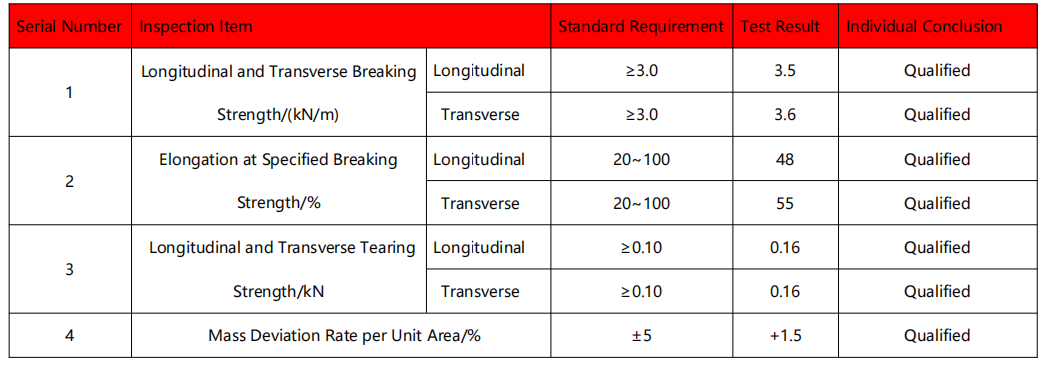

PERFORMANCE INDICATORS

Method of application

Clean the base surface thoroughly Apply waterproof coating. Lay out the polyester fabric, coat it with paint, and brush it smooth Application

Bathroom Waterproofing Basement Moisture Proofing Basement proofing

Tile-roofed House Leak Proofng Gutter Waterproof Swimming pool Product Display

Product Overview

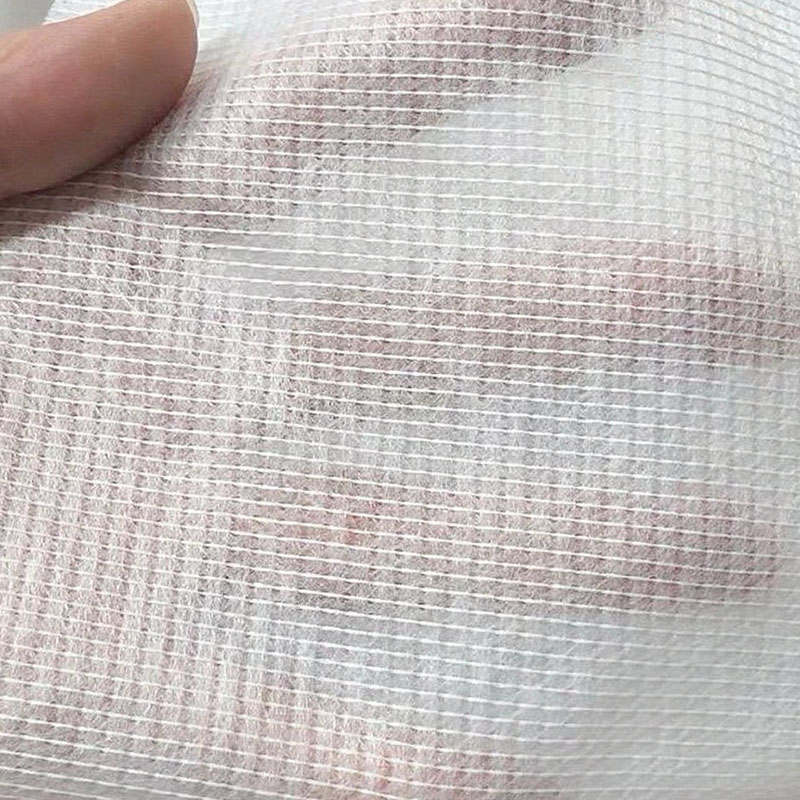

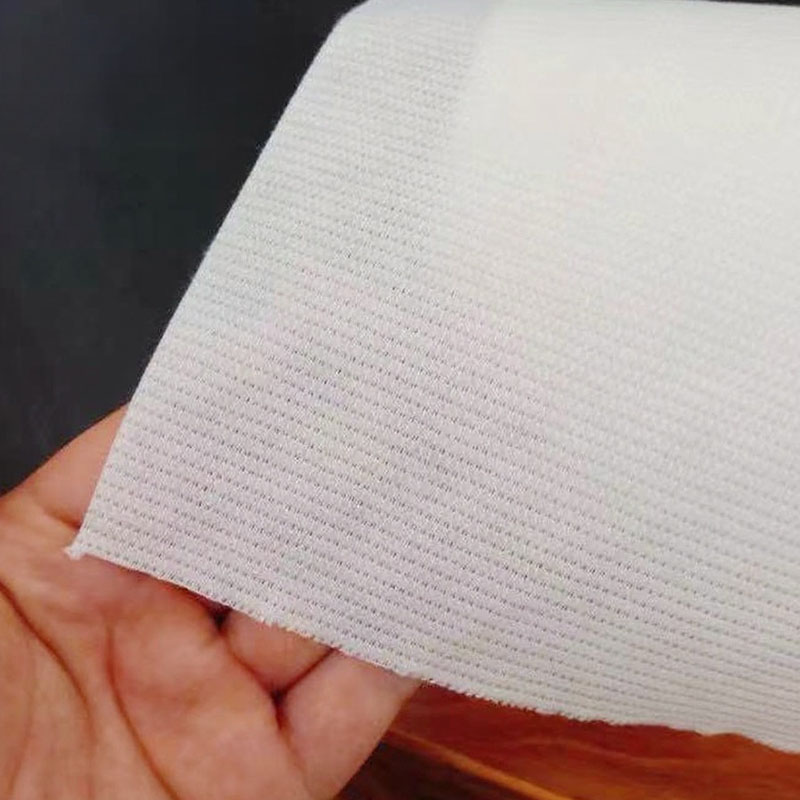

Polyester cloth is a synthetic fiber material made from polyester fibers, which are petrochemical products formed by the polymerization of polyester monomers into linear macromolecular compounds. Polyester cloth is known for its tear resistance, abrasion resistance, waterproof and moisture-resistant properties, as well as its high softness and ease of processing.

Application Scope

Home Furnishings: Widely used in sofas, curtains, bedding, and other household items.

Apparel Industry: Used to make clothes, hats, shoes, etc., due to its softness and ease of processing.

Industrial Use: Employed in the manufacture of industrial products such as filters and conveyor belts.

Construction Industry: Due to its breathability and durability, it is used for thermal insulation, waterproofing, and insulation in buildings.

Other Fields: Also used in making luggage, tents, car canopies, and more.

Product Features

Abrasion Resistance: Excellent resistance to wear and friction, suitable for long-term use.

Tear Resistance: High strength and toughness, offering strong resistance to tearing.

Waterproof and Moisture-Proof: Treated surface provides effective water and moisture resistance, suitable for waterproof material applications.

Corrosion Resistance: Resists most chemical corrosion, making it less susceptible to chemical damage.

Bright Colors: Good dyeing properties allow for vivid and vibrant colored fabrics.

Storage & Transportation of Waterproof Polyester Cloth

Storage Guidelines

Environmental Requirements: Store in a dry, ventilated, and cool warehouse. Avoid direct sunlight and rain. Keep temperature between 5°C and 35°C, and relative humidity below 60%.

Storage Method: Store flat or in stacks, avoiding excessive bending or folding. Rolls should be kept off the ground to prevent moisture and contamination. Different specifications and types should be stored separately and clearly labeled.

Moisture and Mildew Prevention: Use moisture-proof setups like pads or desiccants. Regularly rotate and air out materials to prevent mold growth.

Avoid Direct Sunlight: UV rays can damage waterproof materials and degrade performance. Store in shaded areas or use shading equipment.

Fire Safety: As many waterproof materials are flammable, smoking and open flames should be strictly prohibited. Fire safety equipment should be available.

Transportation Guidelines

Mode of Transport: Choose based on the situation—by truck, train, or ship—opting for economical and efficient transport methods.

Loading and Unloading: Avoid impacts, crushing, and damage. Handle different specifications separately. Use appropriate tools like forklifts or cranes for safe handling.

Packaging Requirements: Ensure secure, sealed packaging to prevent moisture, dust, and other contaminants. Packaging should be durable and include clear labeling: product name, specifications, quantity, manufacturer, and production date.

Application Process of Waterproof Polyester Cloth

I. Thorough Preparation Before Construction

Before starting waterproofing with polyester cloth, comprehensive preparation is essential:

Survey the site to ensure safety and stability.

Ensure the quality of polyester cloth and auxiliary materials meets required standards.

Formulate a detailed construction plan outlining steps and objectives.

1. Substrate Preparation

Check the substrate for smoothness, dryness, oil-free surfaces, sandiness, and cracks. Uneven or cracked areas should be repaired—e.g., leveling with cement mortar or using special repair materials. Clean the surface thoroughly to ensure it’s dust- and debris-free.

2. Material Preparation

Inspect all materials—polyester cloth, waterproof coatings (e.g., polyurethane, acrylic), and auxiliary materials (primers, adhesives). Check specifications, production dates, and quality certificates to ensure compliance. Calculate material quantity based on the construction area to avoid waste.

3. Construction Environment

Maintain an ambient temperature above 5°C and relative humidity below 85% during construction. Avoid adverse weather like rain, snow, or strong winds. Ensure good ventilation to reduce harmful gas exposure.

II. Construction Process

Primer Application

After substrate preparation, apply a primer to improve adhesion and seal micro-pores on the surface. Apply evenly and let dry completely before continuing.Laying the Polyester Cloth

Cut the cloth to the required size and lay it on the primed surface. Ensure overlap is at least 10 cm to maintain continuity. Use adhesive or waterproof coating to bond the fabric tightly to the base without gaps or wrinkles.Applying Waterproof Coating

After laying the cloth, apply a waterproof coating evenly over the surface, ensuring it penetrates the fibers for a dense waterproof layer. Pay extra attention to critical areas like corners and pipe bases, applying additional coats as needed.Multi-Layer Construction (If Required)

For high waterproofing standards, alternate layers of cloth and waterproof coating to increase thickness and durability. Ensure each layer is completely dry before applying the next to prevent bubbles or delamination.III. Key Construction Points and Precautions

Follow waterproof grade requirements strictly, layering fabric and coating alternately for increased durability.

Ensure each layer is fully dry before the next application to avoid moisture issues.

Control temperature and humidity strictly—avoid working in extreme conditions to protect waterproof performance.

Follow mixing ratios as per product guidelines to ensure material quality.

Pay close attention to details like corners, drains, and pipe penetrations for optimal waterproofing.

Protect finished waterproof layers from damage during later construction stages.

IV. Post-Construction Maintenance

After completing the waterproofing layer:

Conduct regular inspections to detect and fix potential leaks early.

Protect the layer from sharp objects or heavy impact.

Promptly repair any damage to maintain long-term waterproof effectiveness.

ABOUT US

CT Waterproof Coatings is a dynamic exporter focusing on supplying waterproof coatings worldwide. We provide solutions to various projects including residential construction, commercial & industrial buildings, infrastructure projects, marine & coastal projects, agricultural projects, roads & highways and storage & warehousing. Established in 2010, we have built a reputation for delivering exceptional value, reliability and unparalleled customer service.

SHIPPING SCENE

FAQ

Are you trading company or manufacturer?

We are manufacturer.So we have a lower price than trading company.

What is the payment way?

TT, L/C at sight, West Union,Online Bank Payment.

What are your terms of delivery?

We can accept EXW, FOB, ClF, etc. You can choose one which is the most convenient for you.

Do you accept OEM or ODM order?

Yes, we accept both OEM and ODM for customers.

How does your factory do regarding quality control?

Quality is priority,. We always attach great importance to quality control from the very beginning to the end. We have a professional QA/QC team to ensure the quality.

How about the delivery time ?

7-15 days after receive the deposit or LC at sight

Do you provide sample ?ls it free or extra ?

Yes,we can provide free sample for quality inspection.According to our company police , you should assume the freight ,and we will return the freight if you place the order.

Why choose us ?

We are professional manufacturer, and we can provide the best product ,competitive priceand excellent service.

Polyester cloth

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.