Hydrophobic Polyurethane Grouting Material

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

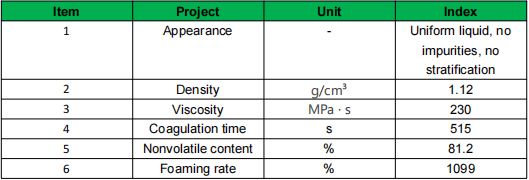

Performance indicators

Advantages

• Excellent hydrophobic properties

• Large penetration radius and solidification volume ratio

• Superior chemical resistance

• Smooth coating surface, abrasion-resistant and mold-proof

• Exceptional bonding performance

• Adjustable curing rate

Applications

Building waterproofing

and leakage sealingFoundation and tunnel engineering

Water conservancy and transportation

infrastructureGeological and mining engineering

ABOUT US

CT Waterproof Coatings is a dynamic exporter focusing on supplying waterproof coatings worldwide. We provide solutions to various projects including residential construction, commercial & industrial buildings, infrastructure projects, marine & coastal projects, agricultural projects, roads & highways and storage & warehousing. Established in 2010, we have built a reputation for delivering exceptional value, reliability and unparalleled customer service.

SHIPPING SCENE

FAQ

Are you trading company or manufacturer?

We are manufacturer.So we have a lower price than trading company.

What is the payment way?

TT, L/C at sight, West Union,Online Bank Payment.

What are your terms of delivery?

We can accept EXW, FOB, ClF, etc. You can choose one which is the most convenient for you.

Do you accept OEM or ODM order?

Yes, we accept both OEM and ODM for customers.

How does your factory do regarding quality control?

Quality is priority,. We always attach great importance to quality control from the very beginning to the end. We have a professional QA/QC team to ensure the quality.

How about the delivery time ?

7-15 days after receive the deposit or LC at sight

Do you provide sample ?ls it free or extra ?

Yes,we can provide free sample for quality inspection.According to our company police , you should assume the freight ,and we will return the freight if you place the order.

Why choose us ?

We are professional manufacturer, and we can provide the best product ,competitive priceand excellent service.

Hydrophobic Polyurethane Grouting Material

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.