Polypropylene fiber

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

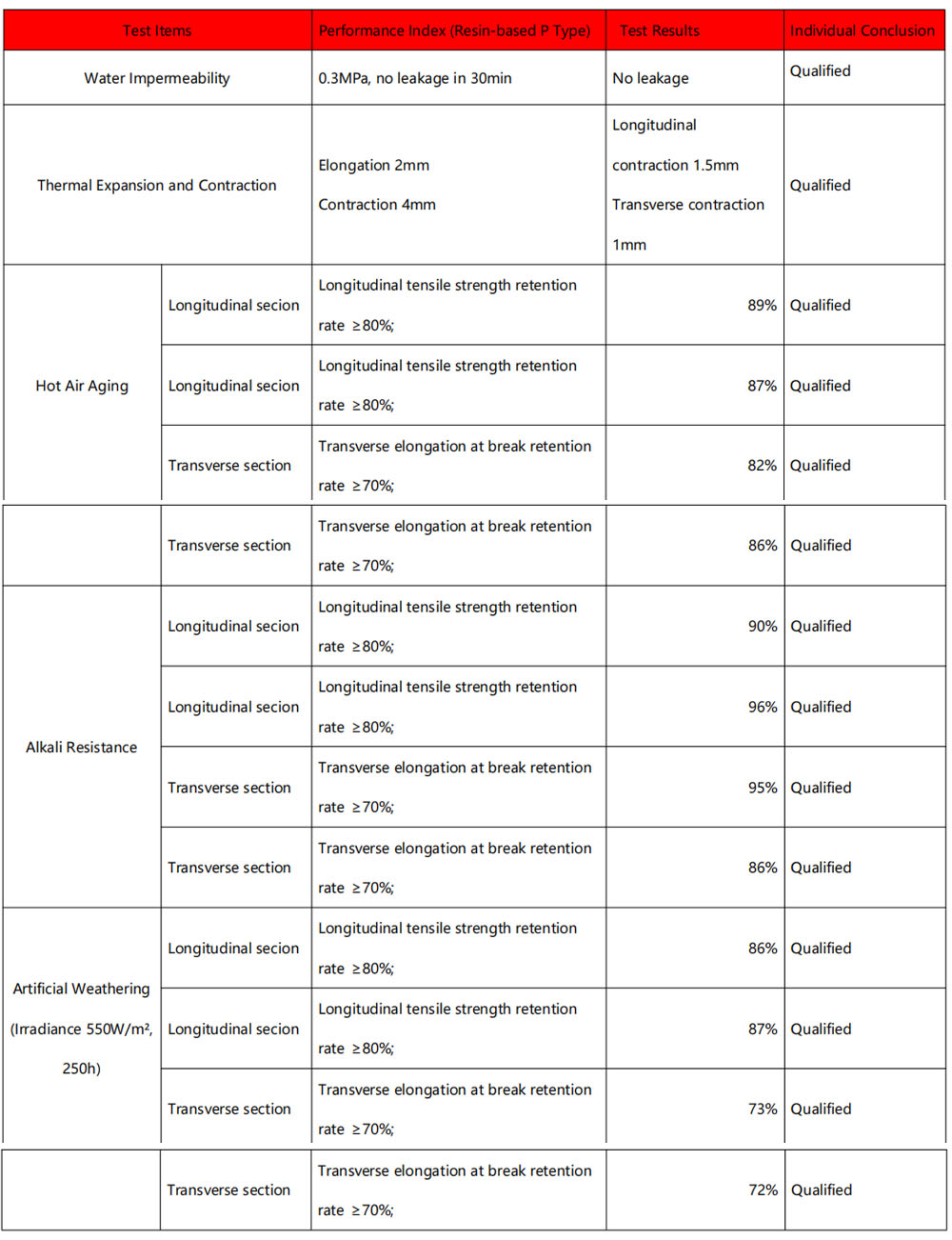

PERFORMANCE INDICATORS

Easy construction

1. Clean the ground.pour the mixedcement slurry onthe base surface.and scrape it flatwith a scraper. 2. When laying thepolypropylene cloth,water and air must bdriven out to ensurethere is no hollowing 3.Apply a protectivelayerof cement slurryon the polypropylenecloth, preferably morethan 2cm Application

Bathroom Waterproofing Basement Moisture Proofing Basement proofing

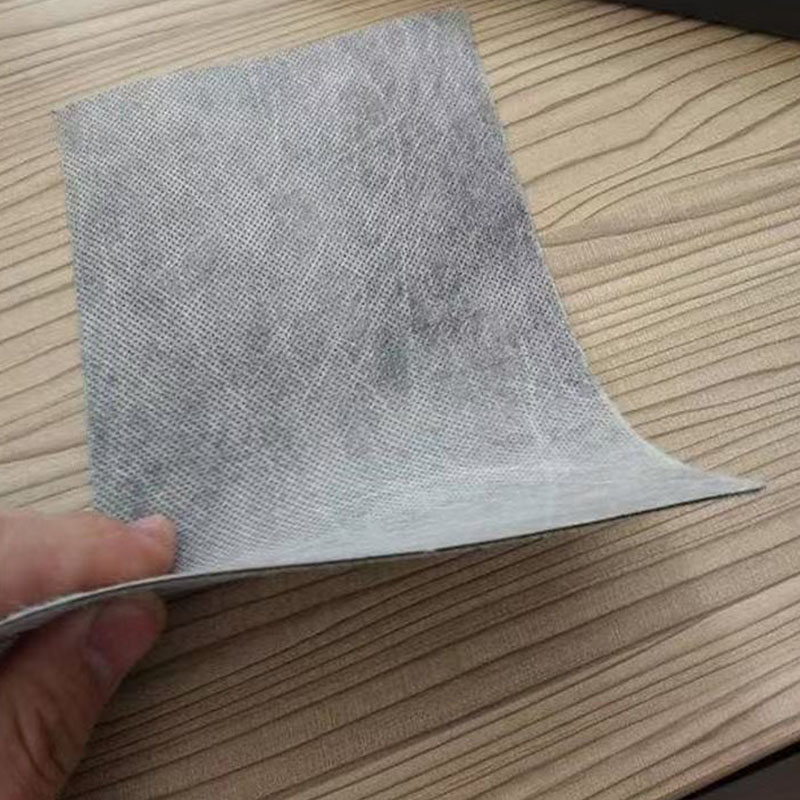

Tile-roofed House Leak Proofng Gutter Waterproof Swimming pool Product Display

Product Overview

Polypropylene fabric is a synthetic fiber made from propylene, a byproduct of petroleum refining, and is commonly known as polypropylene fiber in China. It is made from a plentiful raw material, has a simple production process, and is relatively cheaper than other synthetic fibers. The physical and mechanical properties of the fiber include:

• High strength (short fibers: 4–6 g/denier, long filaments: 5–8 g/denier)

• Similar wet and dry strength

• Low specific gravity (0.91)

• Wear resistance and corrosion resistance.Application Scope

1.Roof Waterproofing: High molecular polypropylene fabric has excellent tensile strength, anti-permeability, and anti-aging properties, making it suitable for roof waterproofing. However, it must not be exposed directly to the roof and should be covered with a protective layer to prevent damage and cracking.

2.Basement and Bathroom Waterproofing: This fabric is also suitable for waterproofing basements and bathrooms. Its nonwoven fabric fibers on both sides allow it to bond with various materials such as cement mortar, making it suitable for waterproofing in damp environments.

3.Water Pools, Reservoirs, and Channels: The fabric is ideal for waterproofing in hydraulic facilities such as reservoirs, pools, and channels. It offers strong anti-permeability and low-temperature resistance, making it suitable for use in ambient temperature environments.

4.Pollution Control in Metallurgical and Chemical Industries: In the metallurgy and chemical industries, polypropylene fabric can be used to prevent the spread of pollution, owing to its excellent chemical stability and corrosion resistance.

5.Indoor Wall and Floor Waterproofing: It is suitable for waterproofing indoor wall surfaces and floors in areas such as hotels and kitchens that require moisture protection.Product Features

• High Tensile Strength: The fabric has high tensile strength and can withstand significant external forces.

• Strong Anti-permeability: It effectively prevents water penetration.

• Excellent Anti-aging Properties: The fabric maintains its performance over time and is resistant to aging.

• Superior Bonding Performance: It can bond well with various materials like cement mortar.

• Good Flexibility: It is easy to bend and work with, making it suitable for various complex construction environments.

• Long Service Life: With proper use and maintenance, the fabric has a long service life.Storage & Transportation

Storage Conditions

• Temperature: The material should be stored in a temperature-controlled environment, avoiding extreme heat or cold. The recommended storage temperature range is between -20°C and 35°C.

• Humidity: Maintain a dry environment to prevent moisture, which may affect the material's performance.Transportation Conditions

• Packaging: Ensure the packaging remains intact during transport to prevent any damage to the material.

Construction Requirements

• Surface Preparation: Ensure the construction site is dry, dust-free, and the substrate surface is flat and secure. Completely remove old waterproof layers, oil stains, and dust. Use a scraper or sandpaper to smooth out any uneven areas. For cracks and holes, repair them with appropriate materials.

• Material Preparation: Prepare high molecular polypropylene fabric (polypropylene geotextile), cut it to the appropriate size, ensuring a 10 cm overlap around the edges. Prepare special cement-based adhesives and other bonding materials, mixing them according to the specified ratio and ensuring uniformity without sediment or separation.Application Process

1.Apply Base Primer: Apply a layer of waterproof primer or base material evenly on the substrate to enhance adhesion between the substrate and the polypropylene fabric.

2.Apply Additional Layers: For complex areas prone to leaks such as corners, pipe roots, eaves, and downspouts, first apply an additional layer of polypropylene fabric. The width of the additional layer should generally be no less than 50 cm.

3.Polypropylene Fabric Installation: Begin laying the fabric from the highest point of the construction area to the lowest point. Spread the fabric evenly on the substrate and use a roller or brush to press it down, expelling any air to ensure firm adhesion without bubbles or wrinkles. For vertical installations, lay the fabric from bottom to top.

4.Seam Treatment: Seal overlapping areas with waterproof edge strips or special seam adhesives. First apply a layer of seam adhesive, then cover with the waterproof edge strip, and apply another layer of adhesive. For larger seams or corners, you can use a double layer of polypropylene fabric for alternating coverage.Precautions

1.Apply Waterproof Base Material: After laying the polypropylene fabric and treating the seams, apply a layer of waterproof base material evenly over the entire waterproof layer to further enhance waterproof performance and protect the polypropylene fabric.

2.Curing and Maintenance: After completion, ensure the waterproof layer cures in a dry environment, avoiding pressure from other construction work or heavy objects. The curing time is about 24 hours, but it may vary based on the environment and temperature.

3.Quality Inspection: Check the waterproof layer for any damage, bubbling, missed areas, or insufficient overlap. If issues are found, repair them promptly.

ABOUT US

CT Waterproof Coatings is a dynamic exporter focusing on supplying waterproof coatings worldwide. We provide solutions to various projects including residential construction, commercial & industrial buildings, infrastructure projects, marine & coastal projects, agricultural projects, roads & highways and storage & warehousing. Established in 2010, we have built a reputation for delivering exceptional value, reliability and unparalleled customer service.

SHIPPING SCENE

FAQ

Are you trading company or manufacturer?

We are manufacturer.So we have a lower price than trading company.

What is the payment way?

TT, L/C at sight, West Union,Online Bank Payment.

What are your terms of delivery?

We can accept EXW, FOB, ClF, etc. You can choose one which is the most convenient for you.

Do you accept OEM or ODM order?

Yes, we accept both OEM and ODM for customers.

How does your factory do regarding quality control?

Quality is priority,. We always attach great importance to quality control from the very beginning to the end. We have a professional QA/QC team to ensure the quality.

How about the delivery time ?

7-15 days after receive the deposit or LC at sight

Do you provide sample ?ls it free or extra ?

Yes,we can provide free sample for quality inspection.According to our company police , you should assume the freight ,and we will return the freight if you place the order.

Why choose us ?

We are professional manufacturer, and we can provide the best product ,competitive priceand excellent service.

Polypropylene fiber

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.